|

| May 08, 2012 | Volume 08 Issue 18 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineer's Toolbox:

GE introduces new high-speed CT scanner for aerospace, automotive parts

System aims to make quality control more precise and up to 200 times faster.

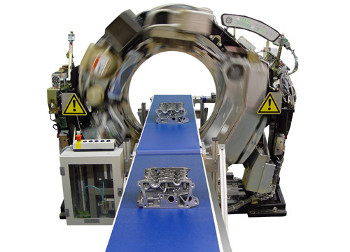

The speed|scan atlineCT system brings super-fast 3D parts scanning and inspection to the assembly line. [Image courtesy: GE]

Ever wish you could see inside, say, a newly cast engine part as easily as they view a 3D CT scan of the human body on one those network-TV hospital shows?

Well now you can.

GE Inspection Technologies recently unveiled a new high-speed, three-dimensional (3D) computed tomography (CT) system that's perfect for the inspection and stringent quality control of light metal castings and composite structures found across the aerospace sector. And with the changes in how car parts are being designed and made, and what they are made of, it's great for that industry, too. The system will be available later this month.

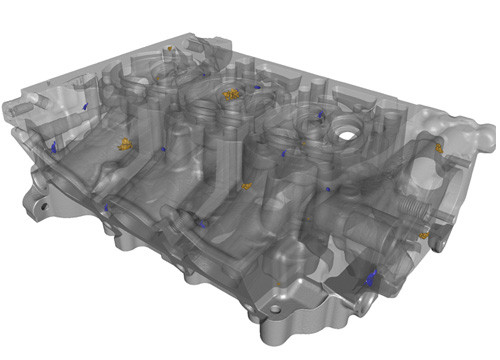

The speed|scan atlineCT system leverages more than four decades of GE innovation and expertise in the healthcare industry to leapfrog conventional 3D CT inspection technology. It operates up to 200 times faster than traditional solutions, according to its maker, and offers important quality-control features that pound the competition, including exact 3D defect location and classification, wall thickness analysis to allow dimensional control, and actual computer-aided design (CAD) data comparison.

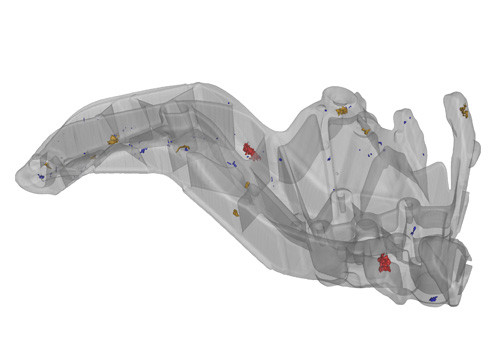

[Image courtesy: GE]

"GE's new inspection system dramatically reduces scan times for an engine cylinder head from several hours with conventional fan-beam CT to less than 2 minutes," says Oliver Brunke, lead CT product manager for GE's Inspection Technologies business. "For the first time ever, the full benefits of 100% 3D inspection can be realized on aerospace production lines. This innovation enables the early identification and correction of workpiece form and size deviations and the detection and classification of foreign materials to significantly reduce reject rates."

[Image courtesy: GE]

The modified GE medical scanner in the speed|scan atlineCT system uses Helix multi-line technology. A gantry with an x-ray tube and corresponding multi-line x-ray detector rotates around the workpiece, which is being passed through the gantry on a conveyor belt. The workpieces are scanned at speeds up to several centimeters per second and are automatically assessed with the aid of GE's own speed-optimized evaluation algorithms.

Inspection is carried out using a breakthrough workflow structure, loading the workpiece onto the conveyor belt of GE's new system, which is placed adjacent to the production line. The continuous CT scan takes place while the software begins volume reconstruction and optimization.

As soon as the workpiece is unloaded, a new one takes its place on the belt for scanning; simultaneously, 3D Automatic Defect Recognition (ADR) is taking place on the first workpiece volume to allow rapid sentencing. The second and subsequent workpieces then follow the same procedure.

The new atlineCT inspection system can handle workpieces up to 300 x 400 x 800 mm in size and up to 50 kg in weight. The machine is built to work 24/7 in continuous operation. Its containment cabinet is suitable for industrial environments with dust protection and thermal isolation. The radiation safety cabinet offers full protective installation and meets both the German RÍV standard and the US 21 CFR 1020.40 standard.

More information should be available soon at GE Measurement & Control.

Source: GE

Published May 2012

Rate this article

View our terms of use and privacy policy